Capabilities

Hole diameter: 0.5mm – 50mm

Thread size: M2 – M24 (metric) / #2–1” (inch)

Tolerance: ±0.01mm

Deep hole drilling up to 10x diameter

Materials: Aluminum, Stainless Steel, Brass, Copper, Plastics

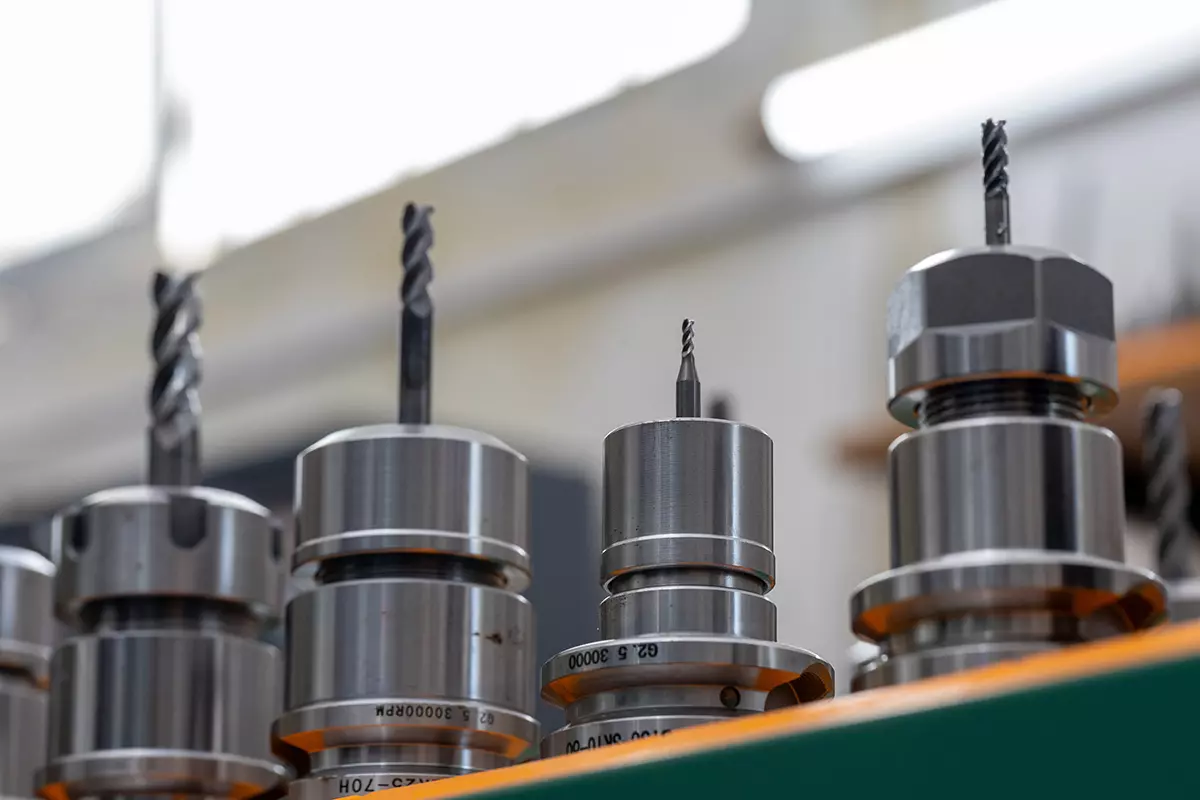

Process Types

Standard Drilling – For through-holes and blind holes

Countersinking / Counterboring – For screw head seating

Thread Tapping – Internal threads for bolts and fasteners

Thread Milling – High-precision alternative for complex threads

Deep Hole Drilling – For components requiring long, narrow holes

Applications

Electronics – Housings, heat sinks, connector holes

Automotive – Engine blocks, transmission components

Aerospace – Structural parts with threaded fasteners

Medical – Surgical tools, orthopedic implants

Why Choose Our Drilling & Tapping?

High Precision – Hole and thread accuracy up to ±0.01mm

Efficiency – Multi-axis machines allow drilling and tapping in one setup

Durability – Strong, reliable threads for long-lasting connections

Versatility – Wide range of hole sizes and thread types supported

Quality Assurance

Thread gauges & pin gauges inspection

In-process monitoring to prevent defects

Consistent thread depth and pitch accuracy

Value-added Services

Combined drilling, tapping, and milling operations

Secondary operations: Chamfering, Deburring, Polishing

Surface treatments for enhanced performance: Anodizing, Plating, Coating

Prototyping and mass production flexibility