Capabilities

Max part length: up to 500mm

Max diameter: 300mm

Tolerance: ±0.01mm

Materials: Aluminum, Stainless Steel, Brass, Copper, Titanium, Engineering Plastics

Batch range: Prototype to high-volume

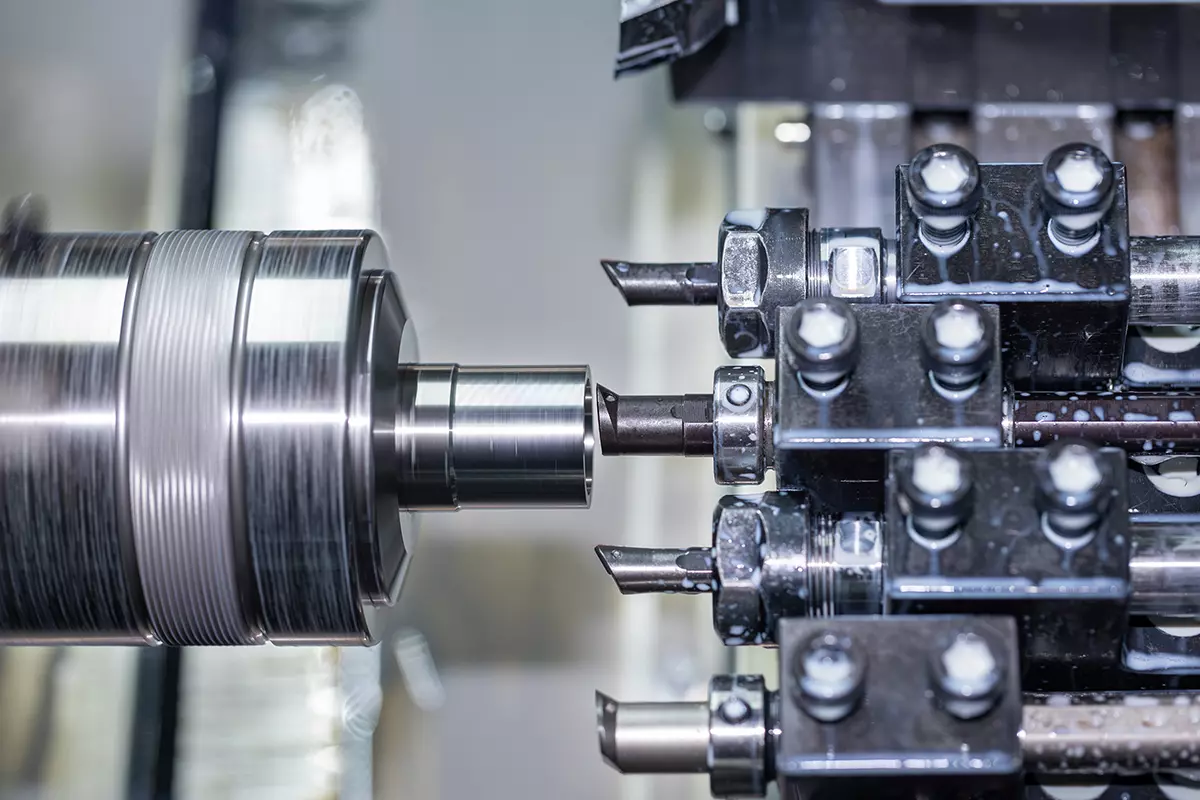

Turning Capabilities

Standard Turning – Ideal for shafts, pins, rods

Grooving & Threading – External and internal threads, precision grooves

Boring & Drilling – Inner diameter machining with high accuracy

Live Tooling (CNC Turning Centers) – Enables milling and drilling in one setup

Our CNC turning services are widely used in:

Automotive – Shafts, bushings, fasteners

Aerospace – Engine parts, landing gear components

Medical – Surgical instruments, orthopedic screws

Electronics – Connectors, housings, precision pins

Why Choose Our CNC Turning?

High Efficiency – Faster machining of cylindrical parts

Tight Tolerances – Accuracy up to ±0.01mm

Smooth Finish – Reduced post-processing required

Flexible Setup – From simple shafts to complex geometries

In-process monitoring for dimensional stability

Advanced measurement equipment (CMM, gauges)

ISO 9001 certified manufacturing system

Value-added Services

Secondary operations: Milling, Drilling, Knurling

Surface treatments: Anodizing, Plating, Polishing, Coating

Assembly support for multi-part components

Flexible production from prototypes to mass production