Hybrid Manufacturing: The New Era of CNC Machining and Additive Manufacturing

Hybrid manufacturing is reshaping modern production. As design requirements grow more complex, the combination of 3D printing and CNC machining provides a new way to achieve accuracy, speed, and efficiency. This approach blends the freedom of additive manufacturing with the reliability of CNC milling and CNC lathes. It creates parts that are lighter, stronger, and easier to customize for industries that demand high performance.

More manufacturers are choosing to 3D print a near-net-shape blank and then finish it using CNC machining. This workflow enables the creation of internal channels, lattice structures, and complex geometries that traditional subtractive machining cannot achieve alone. Once the structure is printed, CNC Precision machining ensures every surface meets tight tolerances. For many aluminum components, final accuracy can reach ±0.01–0.02 mm, offering performance suitable for aerospace and medical applications.

Hybrid manufacturing also reduces material waste. Conventional CNC machining begins with a solid billet and removes a large portion of material, which leads to high scrap rates. Additive manufacturing builds only what is needed. CNC finishing then removes just a small amount of excess material. This combined process can reduce waste by 60–80% and shorten lead times by as much as 30–50%, especially for low-volume or custom parts needed in CNC import supply chains.

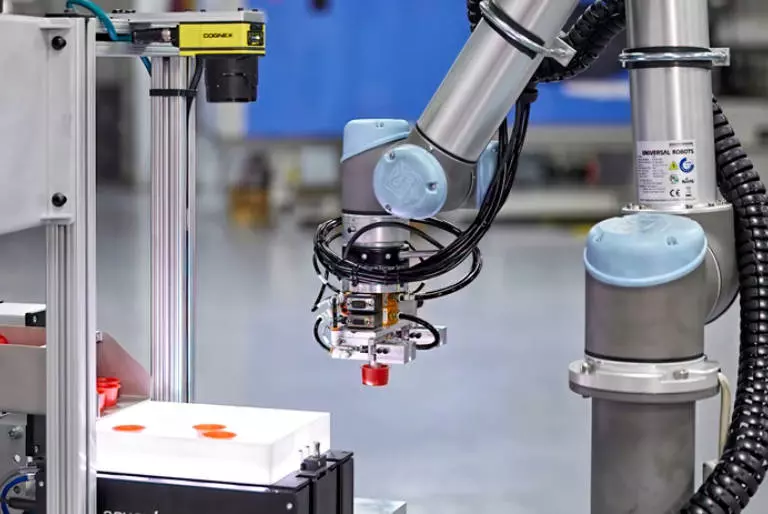

The hybrid workflow is efficient because the part remains in the same coordinate system during both additive and subtractive steps. The machine prints the geometry layer by layer, then switches into CNC machining without the need for new fixtures or repositioning. This reduces human error, improves repeatability, and helps manufacturers deliver stable and reliable CNC Service capabilities. It also supports faster prototyping and stronger consistency between batches.

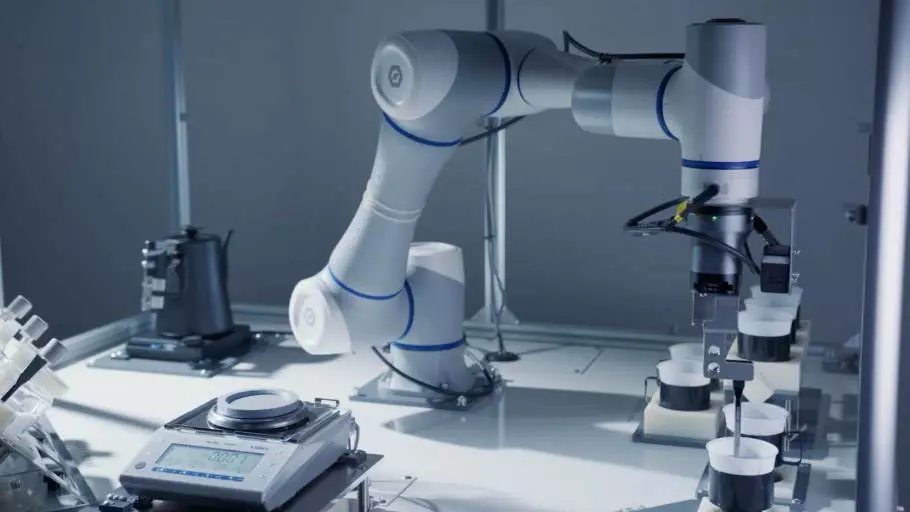

Industries adopt hybrid manufacturing because it meets the demand for lightweight and high-strength components. Aerospace companies value internal cooling channels produced through additive manufacturing, followed by CNC finishing. Automotive teams use the technology to create complex housings and optimized brackets. Medical manufacturers rely on the combination of porous printed structures and CNC-machined precision features. Robotics and automation companies also benefit from the flexibility of producing parts quickly and modifying them with minimal downtime.

Although hybrid manufacturing brings strong advantages, it also introduces new challenges. One major issue is the shortage of skilled technical talent. Modern CNC machines with AI functions and IoT connectivity require operators who understand both additive and subtractive processes. Many companies in the U.S. and Europe report difficulty finding engineers who can program multi-axis systems and manage hybrid workflows. This talent gap slows adoption and increases operational risk.

Another concern is data security. As CNC machines become more connected, the risk of cyber-attacks grows. Hackers may target CAD files, toolpaths, or machine settings. Unauthorized access can cause defective parts, production delays, or serious equipment damage. Manufacturing has become one of the most targeted industries for cybersecurity incidents, making protection of CNC machining data more important than ever. Hybrid manufacturing systems generate even more digital information, which requires stronger encryption, firewalls, and internal access control.

High equipment cost is also a barrier. Hybrid machines are more expensive than traditional standalone CNC milling machines or 3D printers. They require stable environmental conditions, skilled operators, and precise calibration between additive and subtractive modes. For many companies, the better choice is to work with experienced CNC machining suppliers who already operate hybrid systems. This approach reduces cost while still achieving high accuracy and fast delivery.

Despite these challenges, hybrid manufacturing continues to grow. It offers design freedom, lower operational costs, and greater supply chain flexibility for industries that rely on CNC import solutions. As AI technology advances, hybrid machines will improve in accuracy, speed, and automation. This trend will support a new generation of CNC Service providers and help manufacturers deliver reliable, sustainable, and high-precision parts.

Hybrid manufacturing is not a temporary trend. It is becoming a core technology for companies seeking better quality and shorter lead times. By combining 3D printing with CNC machining, manufacturers gain a powerful advantage in producing complex components with outstanding precision. For industries that require accuracy, durability, and innovation, hybrid manufacturing represents the future of advanced CNC production.