How AI and Machine Learning Are Transforming CNC Machining: Technology, Applications, and Industry Challenges

1. AI-Driven Optimization in CNC Machining

Artificial intelligence is now embedded in many modern CNC systems. Instead of relying purely on manual programming or operator experience, AI algorithms analyze data from cutting forces, spindle load, temperature, vibration, and material behavior to optimize machining decisions.

1.1 Smarter Cutting Path Optimization

Traditional CAM software generates toolpaths based on geometric rules. AI-enhanced systems, however, learn from thousands of machining operations and real-world variables.

This allows them to: Reduce machining time by 10–22% through optimized tool engagement; Lower tool wear by up to 15%; Minimize sudden load spikes that could damage the cutter;Improve consistency in high-precision aluminum machining.

For manufacturers offering CNC Precision solutions, even a 5% efficiency improvement can significantly increase output and reduce per-part cost.

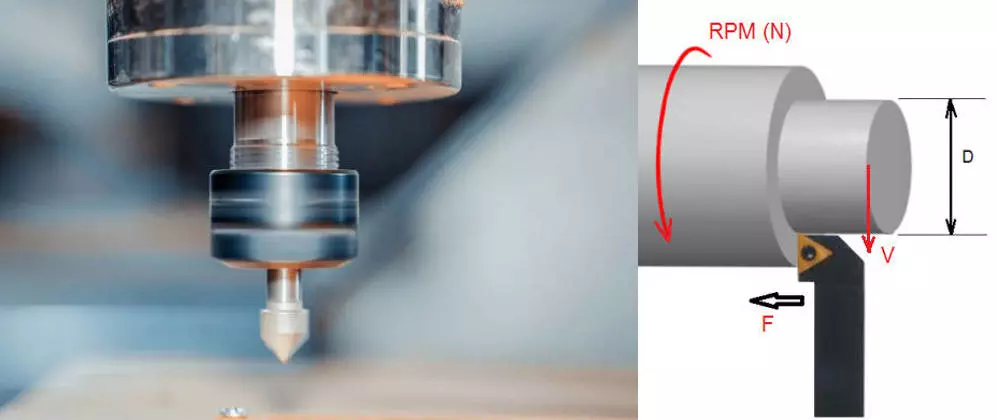

1.2 Real-Time CNC Parameter Adjustment

AI-enabled controllers can automatically adjust: feed rate, spindle speed, coolant pressure, depth of cut.

This dynamic adjustment ensures stable milling performance, especially when machining hard materials such as stainless steel, titanium, and aluminum for aerospace parts.

Industries using CNC milling and CNC lathes benefit greatly from real-time corrections, resulting in smoother surfaces, tighter tolerances, and fewer scrapped parts.

2. AI-Powered Predictive Maintenance Reduces Downtime

Machine downtime is one of the most expensive issues in manufacturing. A single idle CNC machine can cost $1,000–$5,000 per hour, depending on complexity and production bottlenecks.

AI-based predictive maintenance is becoming a game changer.

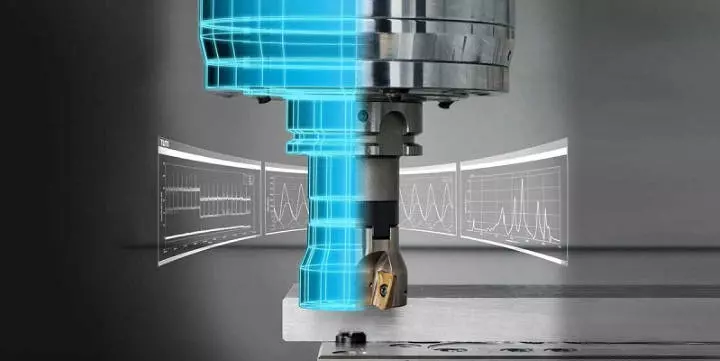

2.1 Monitoring Machine Health Through Data

Using signals from: vibration, spindle temperature, acoustic emissions, lubrication patterns, tool wear sensors.

AI models can accurately forecast when a component is likely to fail.

2.2 Benefits of Predictive Maintenance

AI-driven predictive maintenance helps CNC manufacturers reduce unexpected downtime and improve machine stability. By monitoring vibration, temperature, and tool wear in real time, the system can detect early signs of failure and schedule maintenance proactively. This typically leads to a 30–40% drop in unplanned downtime and extends machine life by around 20%. For high-value CNC milling machines and CNC lathes, these gains improve overall production efficiency and help maintain consistent delivery in global CNC import and export workflows.

3. LLMs: The Future of AI-Generated G-code

A groundbreaking research trend is the use of Large Language Models (LLMs) to generate G-code from natural language descriptions.

Imagine telling a machine:

“Mill a 20 mm pocket, 2 mm deep, using a flat end mill on aluminum.”

And the system outputs complete, ready-to-run G-code.

3.1 Current Research Performance

Recent studies show that LLMs can already achieve 70–85% accuracy when generating G-code for simple CNC milling and turning tasks. These models can interpret basic natural-language instructions and convert them into usable toolpaths, with even better results when paired with simulation or verification tools. While not yet suitable for complex multi-axis machining, AI-assisted programming is proving useful for speeding up prototyping and reducing repetitive coding work in modern CNC machining environments.

4. Combining Knowledge Graphs with LLMs for Intelligent Process Planning

Another exciting direction is integrating Knowledge Graphs (KG) with LLMs to automate high-level manufacturing planning.

4.1 What a Knowledge Graph Brings

A Knowledge Graph organizes key machining data—such as materials, tool types, cutting parameters, spindle capabilities, and tolerance requirements—into a structured, interconnected system. By mapping these relationships, it provides an intelligent database that an LLM can reference when making machining decisions. This allows AI to understand not only individual parameters but also how they interact, enabling more accurate recommendations for tool selection, spindle speed, feed rate, and machining sequence across various CNC milling and CNC lathes operations.

4.2 Benefits for Manufacturers

For manufacturers, combining a Knowledge Graph with an LLM significantly improves process planning efficiency and consistency. It reduces manual decision-making, lowers the chance of human error, and shortens setup time—often by 20–35% in research trials. This integration ensures more stable machining performance, especially in aluminum and high-precision CNC machining tasks. It allows factories to respond faster to customer requests, enhance CNC Service quality, and remain competitive in global CNC import and export markets.

5. Challenges and Risks in AI Adoption for CNC Manufacturers

While AI presents enormous opportunities, it also brings real challenges—especially for growing CNC factories in Asia competing in the global CNC import market.

5.1 High Capital Investment

Adopting AI-ready CNC equipment requires significant upfront cost.

Typical investment ranges:

|

Equipment Type |

Cost Range |

|

5-axis CNC machine with AI features |

$150,000–$300,000 |

|

Industrial robot + automation |

$50,000–$200,000 |

|

Full digital data acquisition system |

$20,000–$100,000+ |

|

High-precision aluminum machining setups |

$50,000–$150,000 |

For small and medium CNC businesses, these costs can be overwhelming without clear long-term planning.

5.2 Technical Talent Shortage

AI integration in CNC machining creates a strong demand for hybrid talent—professionals who understand both traditional CNC skills and modern digital capabilities such as data analysis, automation control, and machine learning fundamentals. However, this skill set is still relatively rare in the global labor market, leading to a noticeable shortage of qualified technical personnel.

This talent gap makes it harder for factories to adopt AI-driven CNC systems efficiently. Many manufacturers experience slower digital transformation, higher labor costs, and increased reliance on external technical support. For companies involved in CNC import and international CNC Service markets, investing in training and upskilling has become critical to staying competitive.

6. The Future of AI in CNC Machining

The convergence of AI, robotics, and digital manufacturing will define the next decade of industrial evolution. Key trends to watch include:

AI-driven autonomous machining

self-correcting CNC machines

fully automated aluminum machining cells

LLM-enhanced CAM that eliminates human coding

real-time data networks across global CNC factories

Factories that adopt AI early will gain a strong advantage in quality, speed, and technological capability—critical factors for success in overseas CNC import and export markets.

At last, AI and machine learning are reshaping CNC machining, from intelligent toolpaths and predictive maintenance to automated G-code generation and optimized process planning, all comprehensively improving machining accuracy, reducing costs, and enhancing the global competitiveness of manufacturing companies.

While high investment and a shortage of skilled technical personnel remain challenges, companies that can proactively plan and effectively apply AI will gain a leading position in the CNC milling, turning, aluminum machining, and global CNC service markets, leading the next stage of intelligent manufacturing.